A reliable partnership in extreme conditions gives Valmet peace of mind

Valmet is a global leader in process technology and automation solutions, driving sustainable industrial development with its innovative solutions. In 2024, the company achieved a revenue of €5.4 billion and employs over 19,000 experts worldwide.

Valmet’s Automation Systems business line, with a revenue of €646 million in 2024, offers top-notch technology for the challenging needs of the pulp, paper, board, tissue, energy, and marine industries, ensuring process efficiency and sustainability. Long-term collaboration with customers and industry leaders has made Valmet a pioneer, with its analyzers and measurement solutions providing the best value on the market.

The long-term collaboration between Bevenic and Valmet

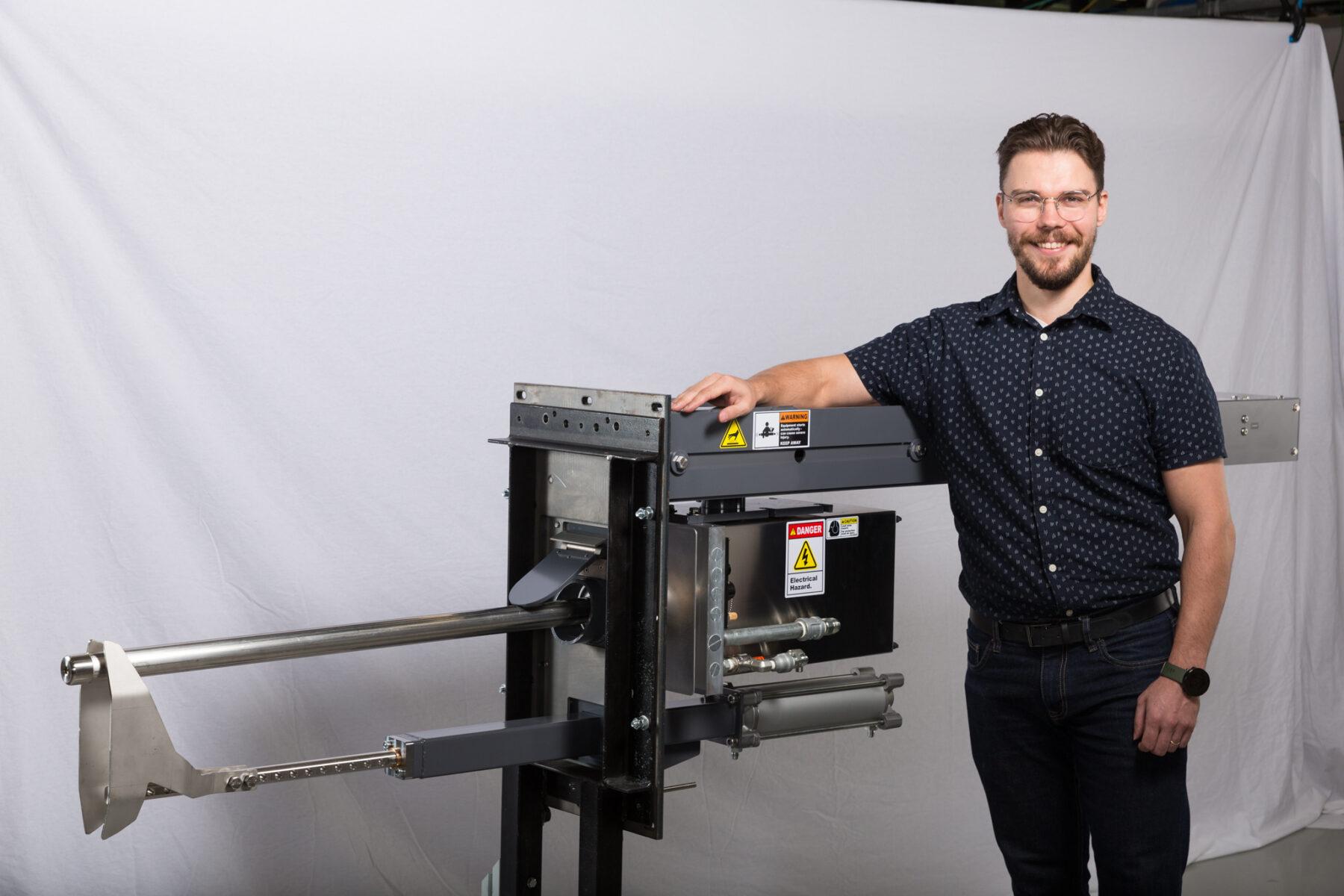

The collaboration between Bevenic and Valmet began several decades ago, and satisfaction with the partnership and quality in other business areas has expanded through internal recommendations over the past year to include the Automation Systems business line’s Boiler Diagnostics Systems products. The product group needed to find a new supplier for an optical device operating in extremely demanding conditions, as challenges had begun to arise with the manufacturing partner operating on another continent. A manufacturer was needed who could produce both parts and subcontract complete optical assemblies.

“The flawless operation and image quality of the furnace camera in extreme conditions are critical,” says Timo Ojanen, Manager Boiler Diagnostic Systems – furnace cameras and acoustic pyrometers, which are thermometers specifically designed for measuring high temperatures.

Smoother production and real cost savings through collaboration

During the project, Bevenic provided Valmet with a comprehensive solution that streamlined production management and significantly reduced their extra workload, allowing them to better focus on their core business. Bevenic independently managed material handling, component procurement, and storage through its own supply channels, saving the customer time, effort, and costs.

It was also important for Valmet that Bevenic strictly adhered to their documentation requirements and that the manufacturing documentation could be shared directly. This enabled a smooth development process, where minor adjustments quickly led to a finished product without unnecessary prototype iterations.

A proactive approach strengthened trust during the project

“During my visit to Bevenic’s Leppävirta unit, I was impressed by Bevenic’s proactive approach and expertise. They actively presented development suggestions to improve product quality and cost efficiency, which strengthened our trust. Genuine customer orientation and solution-focused operations made the collaboration smooth and productive,” says Timo, and continues, “Bevenic’s strong supplier network and comprehensive procurement process are essential parts of successful customer management. Reliable supply chains also give us peace of mind, ensuring we can deliver our customers’ orders on time. This is especially critical in industries where schedules and quality are key.”

Careful selection of components ensures reliability in extreme conditions

Complex technical systems and critical components. For example, in camera products, the quality of optics is crucial as it affects the image quality we offer to our end customers and the product’s reliability in extreme conditions. Bevenic’s expertise and careful selection of components ensured that the optics withstand cooling temperatures of up to 1500 degrees Celsius and operate reliably even in the most demanding environments,” says Timo.

“During the project, we particularly appreciated Bevenic’s independent and proactive approach. Supply chain management, development of technical solutions, and active collaboration saved us time and resources,” notes Timo, and continues, “High-quality documentation, smooth communication, and a comprehensive supplier network laid the foundation for a long-term and reliable partnership.

Bevenic is a globally competitive partner

“For Valmet, key partnership criteria include quality, delivery assurance, proactivity, and competitiveness. The supplier must be genuinely competitive on a global level. There were several options when searching for a new partner – Bevenic was able to offer a solution that met both quality requirements and international competitiveness,” reveals Timo.

As a global company, Valmet places significant weight on a worldwide supplier network, but domesticity also matters for operational smoothness. Collaboration with Finnish suppliers is seamless, and Valmet feels that Finnish suppliers genuinely value the customer relationship, which is reflected in the quality and flexibility of the service – this significantly promotes project success.

When the collaboration began, the goal was to establish a stable supplier relationship and ensure that optical components are delivered smoothly to global markets.

“In the long term, the solutions provided by Bevenic support the growth and development of the customer’s business. In the future, the collaboration may expand with new products and product improvements, and discussions about further development are always open,” says Timo Ojanen.

References

Read more about our references

We have a range of customer stories showcasing how our solutions have supported different industrial needs. These stories highlight our commitment to quality, reliability, and tailored solutions that meet the specific requirements of our clients.